SHAFT TEST EQUIPMENT

CLUBFITTING, CLUBMAKING EQUIPMENT

JTCLUBS has a full assortment of professional equipment for analyzing shafts, measuring club specifications, fitting and building clubs, and swing analysis. Here are some of our instruments and methods.

Accuracy and precision

Accuracy indicates how correct (free from error) is the measurment; precision is how closely the measurement can be repeated. Calibrating measuring instruments with known standards is important for accuracy. Knowing the specifications and tolerance of the measuring instruments is important for precision. Both accuracy and precision are needed in fitting and building the best custom clubs.

FlightScope X3 radar launch monitor for club performance

A radar beam at 10 GHz is transmitted from the launch monitor to be reflected by the golf ball and by the clubhead. The Doppler reflections are detected by a receiver array in the monitor, and the phase differences in the signals are measured as the clubhead moves through impact and as the ball travels on its trajectory. Direct measurements of clubhead and ball with unique FlightScope analytical tools are not surpassed by any other commercially available launch monitor for accuracy and detail. Our X3 upgrade is the most accurate launch monitor made by FlightScope, and we keep both software and firmware current.

K-Vest 3D motion capture systems for swing analysis

A small motion detector is placed on the back of the pelvis, between the shoulder blades, and on the back of the lead hand. Each one senses rotational speed around axes of bend, tilt, and turn through the swing. Changes in body angles, speed, and timing are measured directly by the K-Vest and matched to your 3D images to reveal swing biomechanics. It overcomes the prespective errors and assumptions that are limiting in conventional video methods and video game cameras. The K-Vest measures your range of motion and calculates your swing efficiency to understand what you need for an effective golf swing. We have two systems and all software modules including the K-Trainer and K-Health applications. All data collected are compared to extensive swing databases so that you can evaluate the results.

Digital video cameras, including RED 8K Helium, for video capture

Swing motion is captured at video frame speeds of 240 fps or higher resolution as needed to reveal swing details that are obscured at conventional video speeds. We can show exactly where you release the club and where it's optimal for you to release it.

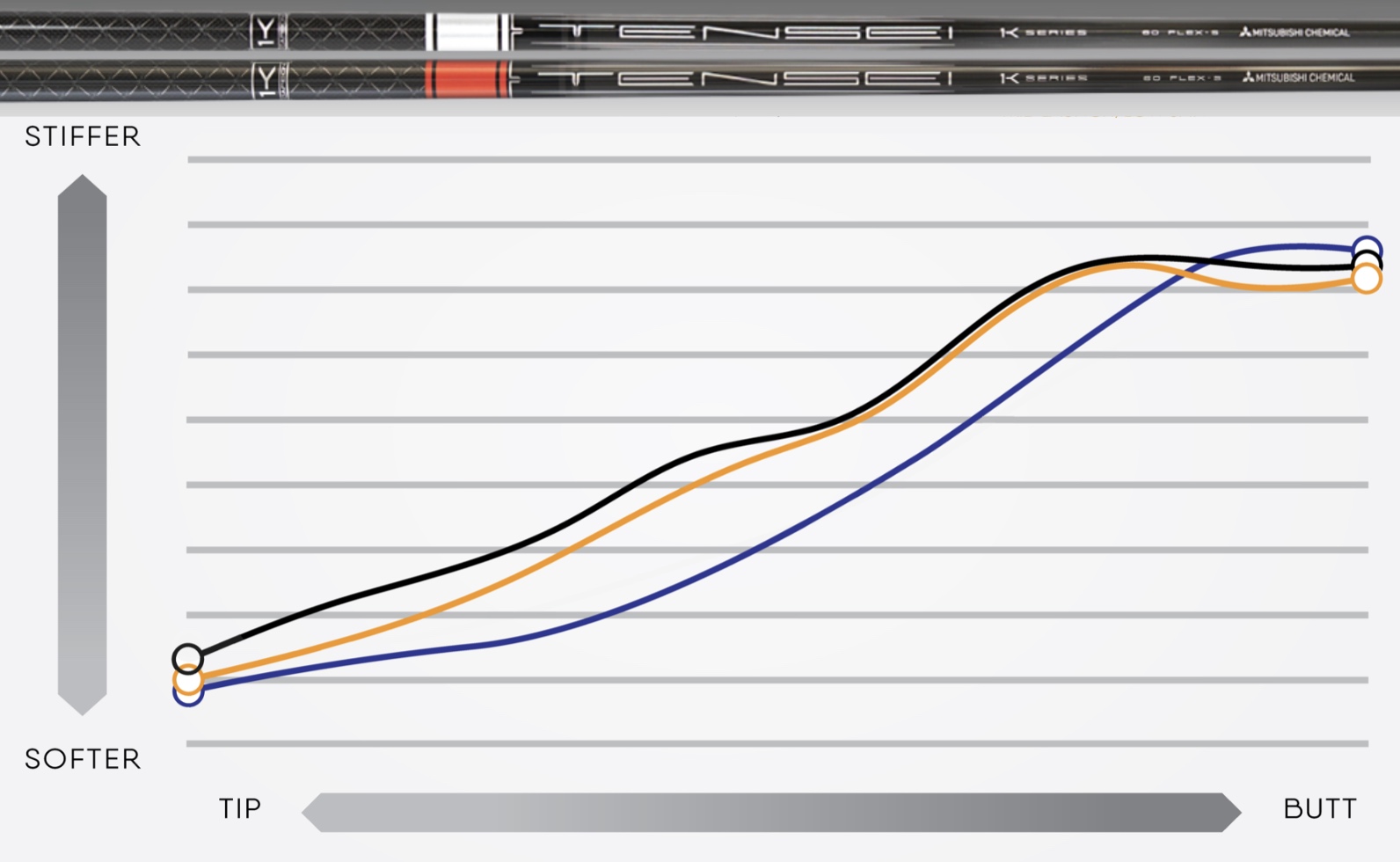

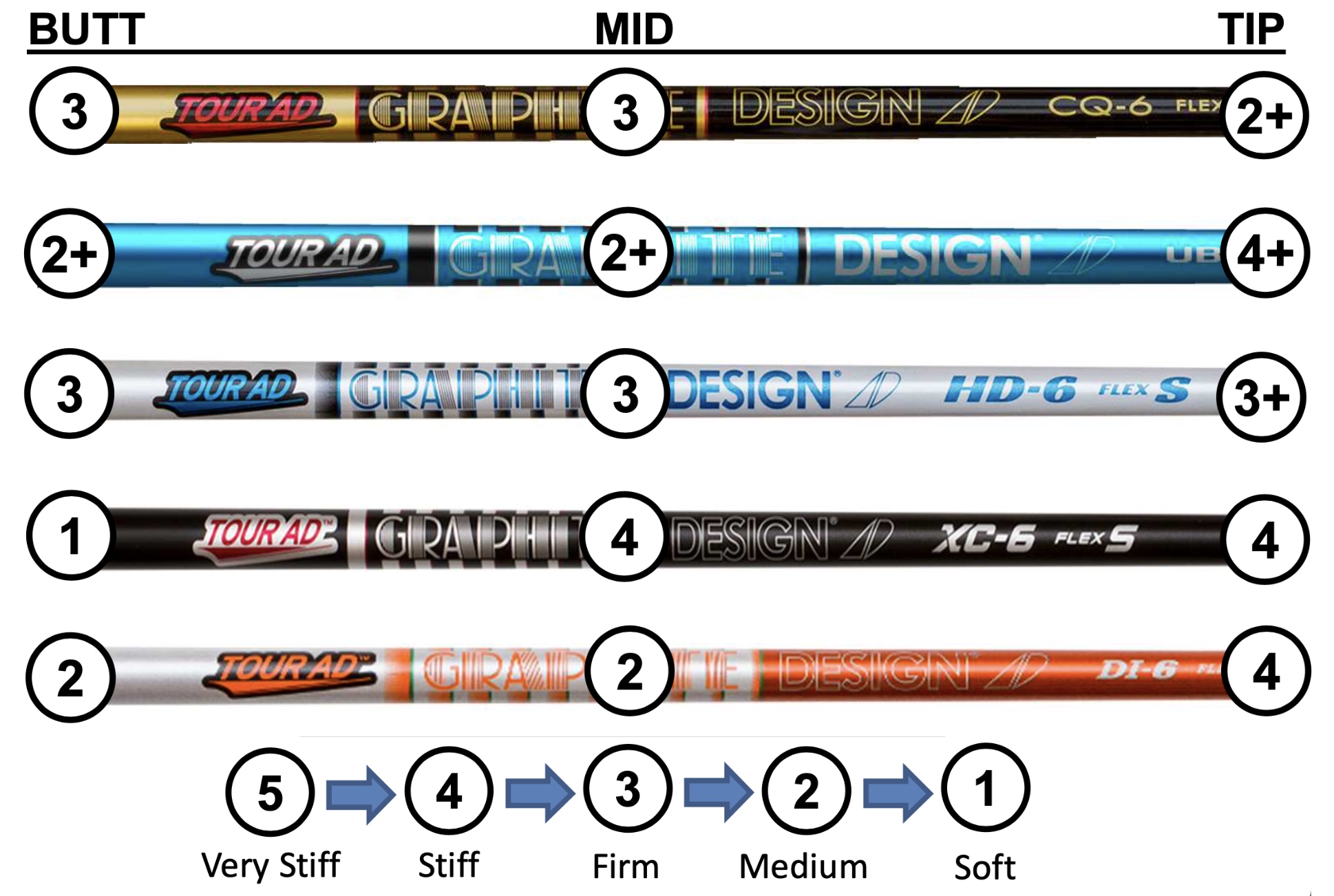

EI machine by Russ Ryden for shaft stiffness profiles

The stiffness properties of shafts are measured at one-inch increments along the length of a shaft to reveal a detailed analysis of how changes in flex are distributed through the shaft. This instrumentation overcomes the damping and averaging limitations of conventional frequency profiling and provides far more useful indicators of shaft flex for fitting. Optimum matching of bending profiles to your swing mechanics is essential to getting the best overall shaft flex for your clubs. EI profiling shows how flex varies throughout the length of the shaft. For example, a soft or firm midsection affects how the tip section responds to shaft load during the swing. In shaft design, the mid section is a major influence on ball trajectory. If you fit or buy shafts based on commonly used butt flex ratings (e.g., R,S,X), you miss the essential features that influence ball trajectory.

NF4 shaft bending machine for differential deflection measurements

A small load is applied to each end of the shaft (preload), then the tip is deflected by an additional load. The difference between preload and final tip load is an indicator of how the shaft might be deflected by your swing motion. The preload allows for meaningful deflection measurements by limiting the effects of spine artefacts that are a consequence of shaft manufacturing processes.

MOI machine by Auditor for club and shaft measurements

Moment of inertia of a club is measured to characterize the force required to swing each iron (or wood, hybrid, or wedge) in a set. MOI is a more useful measure of club balance than conventional swing weight. MOI-matching irons and wedges promotes swing consistency.

Torque machine (digital) by Auditor for shaft measurements

The resistance of a shaft to a standard twisting force (torque) is measured. Since each shaft maker uses different measurment methods, we use our own instrument to analyze and compare shafts from different manufacturers by a standard technique. It's the most reliable approach to understanding the effects of shaft torque on your club's performance. Torque is being recognized as an important parameter in shaft fitting. Excessive shot dispersion is often due to a shaft torque that's too high for the player -- it's important to know whether your shot dispersion is due to a poorly fit shaft or technique inconsistency due to loss of posture during the swing.

Frequency (cpm) shaft analyzers by Auditor and Mitchell

Frequency of shaft oscillation under a standard tip load is measured. Our calibration tools and air-pressure clamp frequency machine allow for accurate analysis and comparison to factory measurements.

Iron and Putter bending machines by Mitchell and MR3

We use industry standard bending machines and heavy duty bending bars to adjust forged carbon steel and soft-cast clubheads with utmost care and precision. Our putter bending machine has the same design as used by leading putter engineers.

Boditrak pressure mat

Changes in the pressure that each foot exerts on the ground during a golf swing are measured to reveal the movement pattern of the body's center of pressure. The subtle timing of pressure shifts between heel and toe at address to the trail side and the lead side are keys to understanding how power is generated and delivered to the ball through impact. The pressure mat detects key changes not seen by video methods.

Loft / lie angle gauges for club head measurements

We use precision milled gauges that we calibrate with known standards for a higher level of accuracy than can be measured by standard bending machines. We determine the optimum lie angles for your irons using a dynamic method that overcomes the errors often yielded by conventional lie boards.

Grinding machines for custom grinds of wedges and irons

We use industrial grade bench-mounted grinding wheels and belt machines for precise crafting of clubhead shapes and angles.

Full collection of professional club building tools and machines

We provide complete clubfitting and clubmaking services with highest craftsmanship, skill, and accuracy.