Tip Trim Driver Shafts?

Our general advice on whether or not you should have the shafts in your driver trimmed when building your club is straightforward and uncomplicated: don't do it. OK, if that's too extreme and you absolutely positively believe you must cut something, then maybe a half inch when you are in between flexes but take note that just about every premium shaft maker in the industry recommends no tip trimming on their driver shafts.

We know tip trimming is a common practice by a wide range of clubmakers both professional and amateur, but just to be clear our advice is: don't do it. Don't request it. Don't have it done on your driver. If someone wants to hack an inch off the tip of your costly new shaft just ask why not jump up a flex in stiffness or 10 g in weight and retain the performance design the shaft engineer intended. Or try a different shaft.

We were motivated to write this blog because of how frequently we encounter this practice with shafts that were not designed to be tip trimmed for use in drivers. We have seen some truly outrageous trimming done on driver shafts that effectively ruined the performance designed into them. OK, we know we'll be challenged on this recommendation. So here's why we take this view.

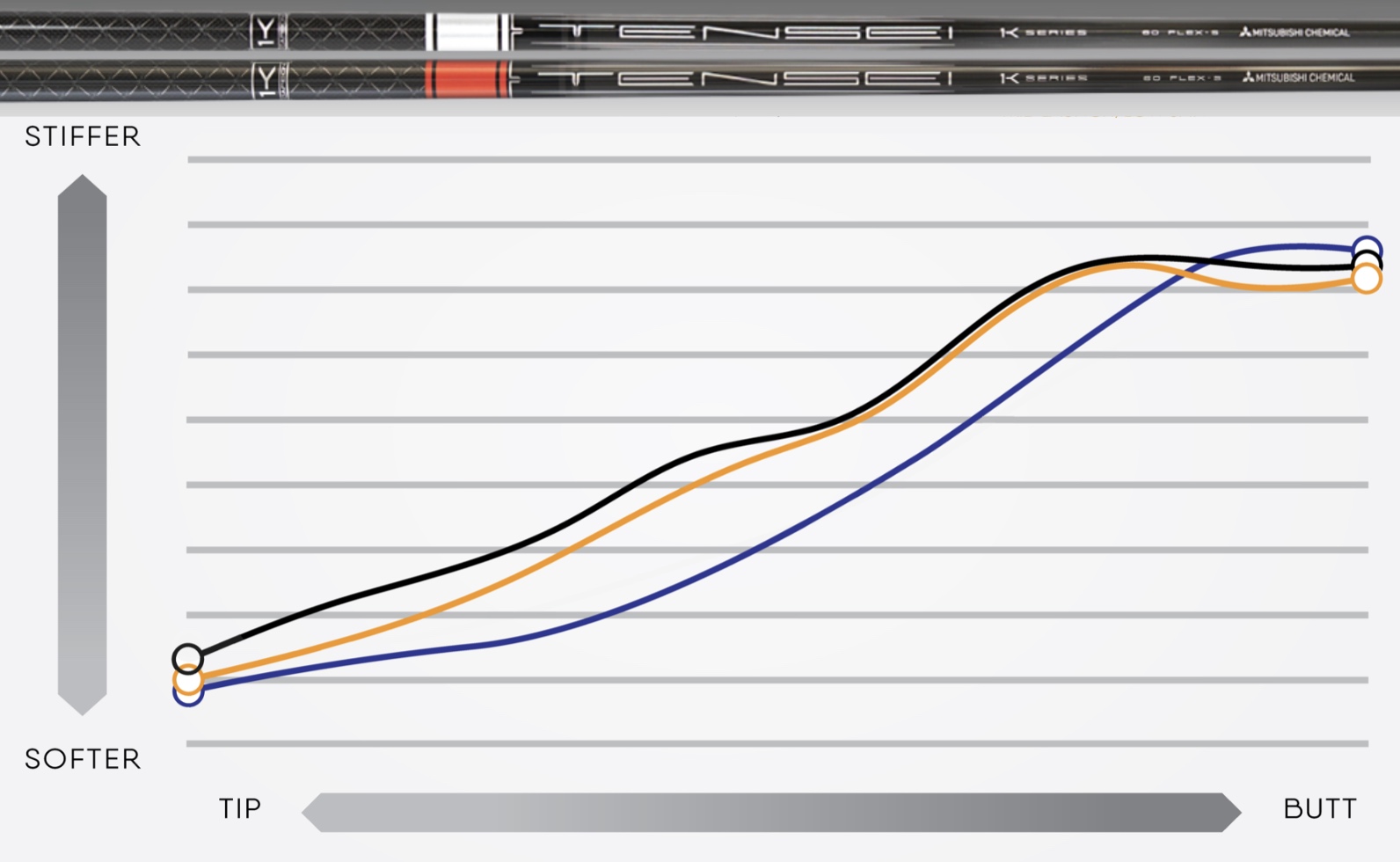

First, let's consider how shafts are designed by shaft engineers. Driver shafts are built to have a short parallel tip section to allow insertion into the clubhead with enough extra length to allow for the stiffness and torque of the tip region to respond fully to the swing motion.

The parallel tip section is 2.5 inches to 3.0 inches on most premium shafts. With a common hosel depth of 1.5 inches to 1.75 inches, there's not much allowance for trimming before affecting performance of the design. Trimming 1.5 inches to 2.0 inches doesn't make any sense to us with these shafts. Even an inch is highly questionable -- we are talking driver shafts here, not fairway woods or expensive alignment sticks.

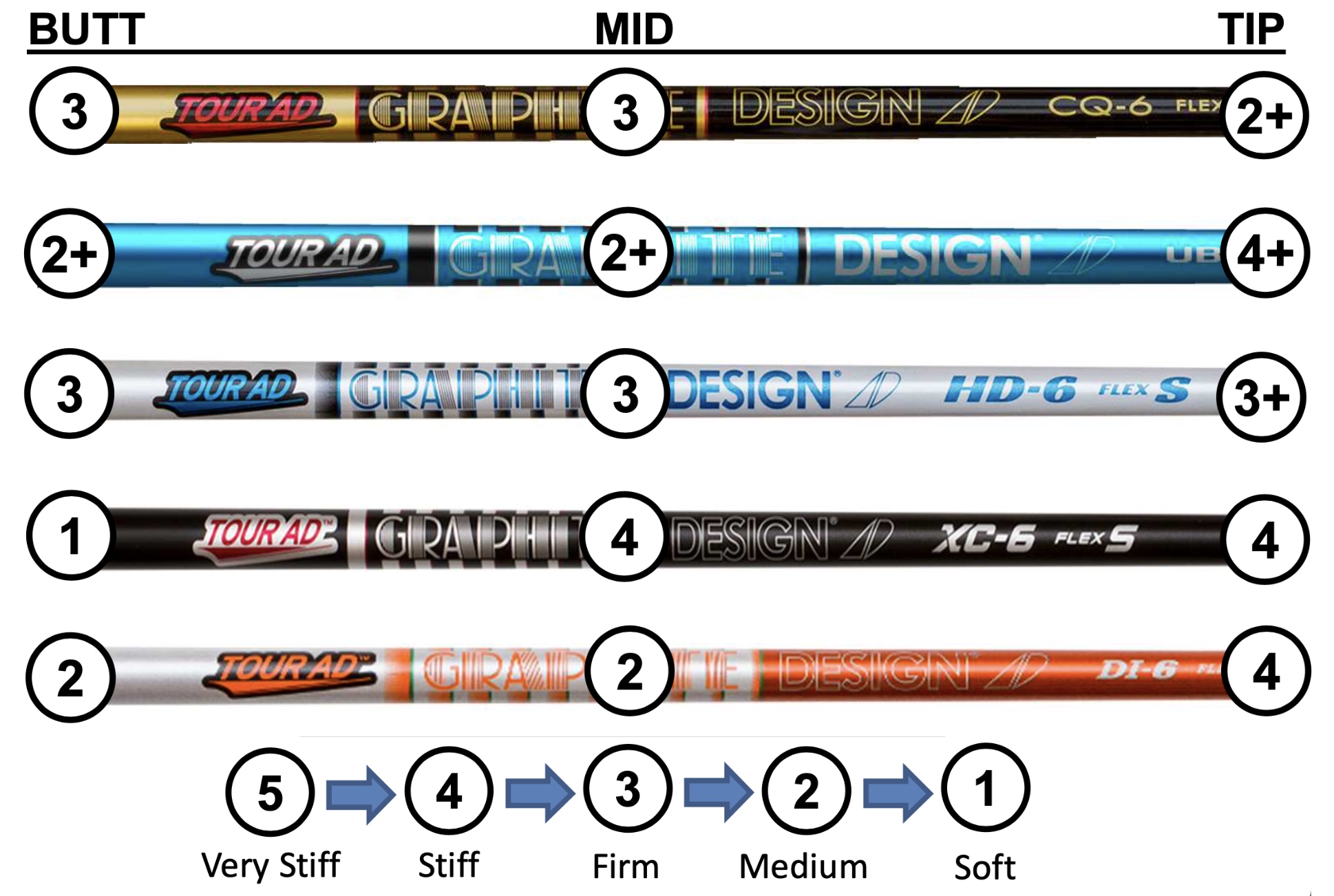

If you like the performance and feel of a particular shaft in your clubfitting session but want a stiffer or more controlled feel, then try a stronger flex from the same manufacturer or try a similar EI stiffness profile from a different source. In that way you will keep the responsiveness and control that works for you. There are so many options for using stiffer or heavier shafts to achieve a desired feel, it takes away just about all the arguments for trimming. So why do it?

We think the current questionable practice of trimming driver shafts comes from earlier days of clubmaking when options for shaft design were limited, production techniques were less sophisticated, steel shafts in drivers were common, parallel tip regions were longer, graphite shaft technology was new.

Is there ever a circumstance where tip trimming a driver shaft is reasonable? Well, we don't rule out a half-inch trim but we still ask why is it being done, what alternatives have been investigated, and have the effects on shaft feel been considered? In our experience, there is almost always an alternative to shaft trimming that should be explored before over-riding a particular performance design.

I recognize that the pot of common practice is being shaken not stirred, but it's a point that bears discussion. Let me know what you think. Send me an email and I'll follow up on a subsequent blog post.

John Taylor

John Taylor