Shaft Flex Rating

Flex is a general term for describing shaft stiffness. Simple rating systems have been used to indicate stiffness. The most common rating system is the LARSX classification: Light (soft flex), Amateur (moderately stiffer than L), Regular (intermediate flex), Stiff, Extra stiff. Alternative terms, e.g. Ladies, Senior, Firm, Tour Stiff have also been used.

There are no industry-wide standards for flex since each manufacturer uses their own measurement protocols. R-flex in one brand can be S-flex or A-flex in a different brand. Some companies go a step further by changing the flex ratings for shafts between their own model lines. How did flex ratings get into this mess and what does it mean for golfers?

An early system still in use today for estimating flex is to weigh shafts. A heavy steel shaft has a stiffer flex than a lighter weight shaft in these models. The problem with this static measurement is that it does not account for loading and unloading of shaft energy during the swing. Variables like shaft diameter, wall thickness, taper of the shaft from grip end to tip, weight distribution through the shaft are ignored.

In the 1970's Joe Braly at Brunswick Golf/Precision Golf introduced a numerical system to describe shaft flex. It depended on a technique in which a shaft is clamped at the butt end, a standard weight attached to the tip end, the tip deflected then released, and shaft oscillation frequency measured. The data correlated with empirical findings on the relationship between flex preferences and swing speeds of pro golfers with their irons.

Here's an example of how this number system was related to swing speed for a 5-iron built to standard weight and length, as extrapolated from Brunswick/Precision's Fitting Guide. Subtract a Frequency Coefficient factor of 30 from the measured swing speed, then use 10% of this value to define the shaft flex. For example, an 85 mph clubhead speed would yield a 5.5 flex number.

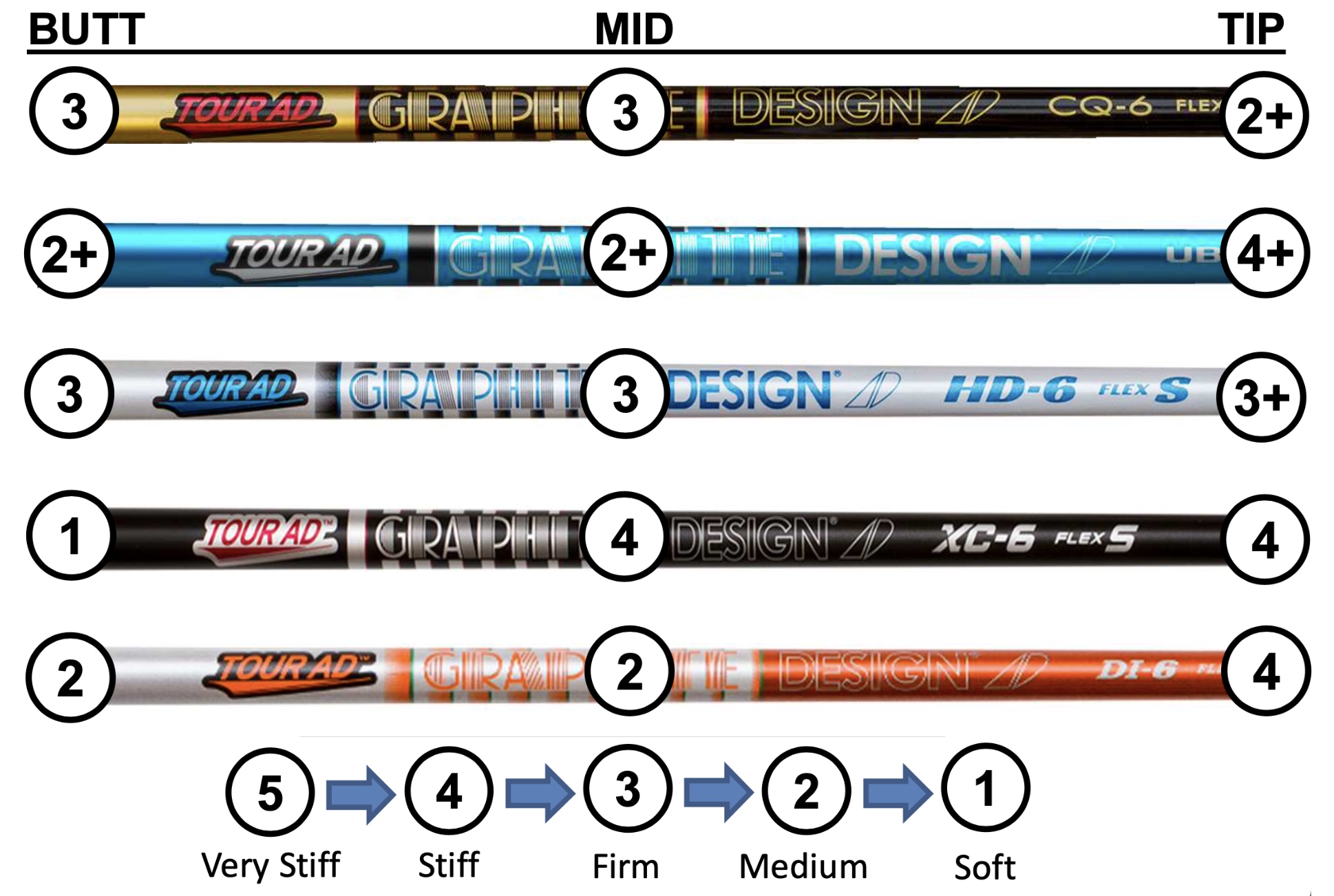

Frequency Coefficient Matching (FCM) became the basis for building a flex-matched set with Rifle shafts, and a similar fitting system was developed by True Temper for Black Gold shafts. The PCS clubfitters group adapted the concept but made arbitrary changes that generated different flex numbers. This system was extended to a 3-number system for indicating stiffness of butt, mid, and tip sections of shafts following general guidelines described by Wishon Golf.

Unfortunately single letter, single number, and 3-number rating systems based on frequency measurements place excess emphasis on the butt end of the shaft where the large diameter yields the stiffest flex. Details in the distribution of stiffness through the length of the shaft are obscured by clamping effects and tip weights. However, shaft oscillation methods can be useful in identifying planes of flex stability.

Analysis of shaft loading characteristics and the refinement of production methods and materials have allowed modern shaft engineers to design shafts with variable stiffness regions along their length by varying shaft diameter, wall thickness, elasticity of materials, and manufacturing technologies. Different regions of stiffness can be designed at local regions of the shaft to achieve major effects on feel and performance.

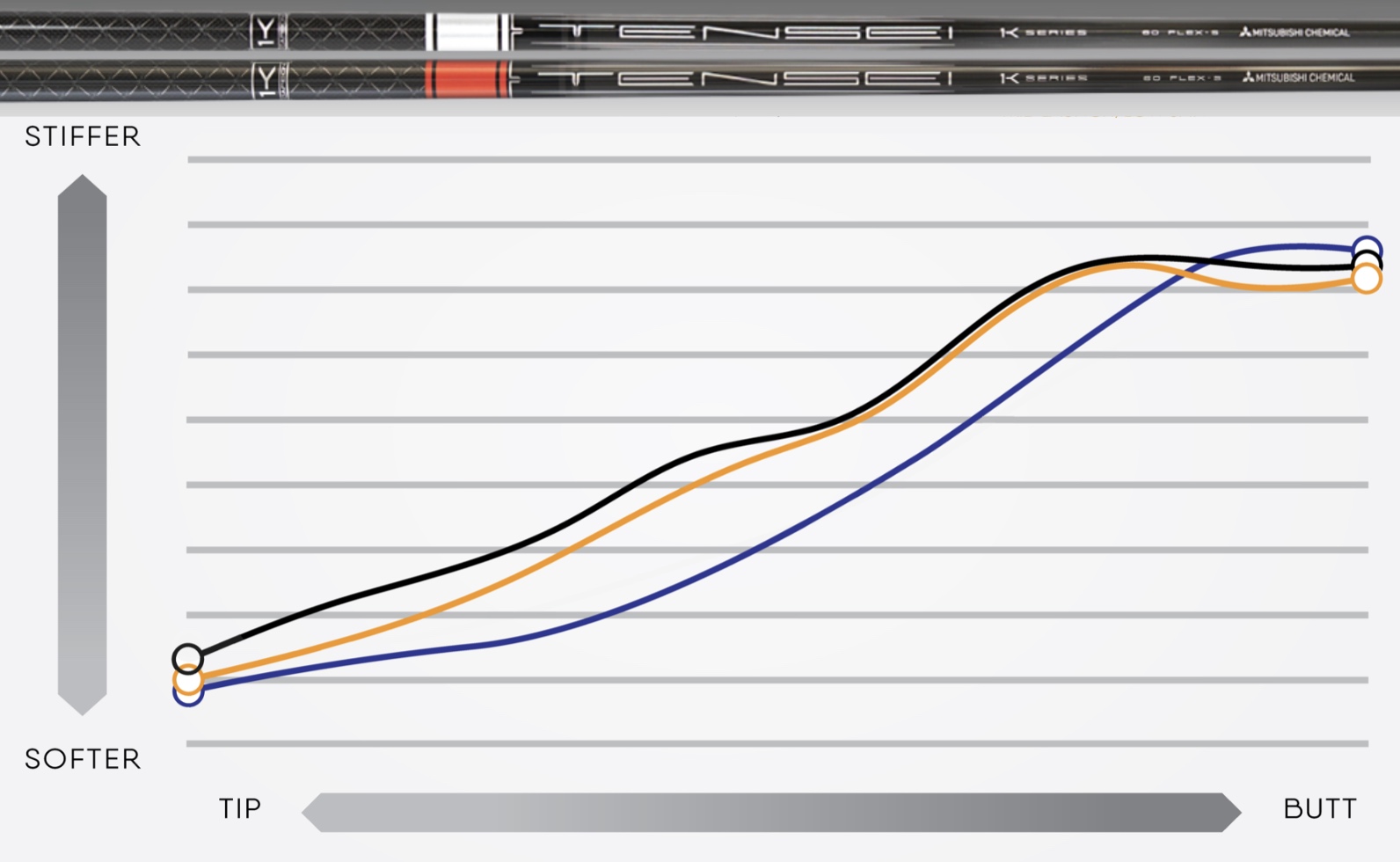

Shaft wall elasticity (E) and resistance (mechanical inertia) (I) to strain can be measured along the length of the shaft for graphs that indicate stiffness in a meaningful way. In this technique a calibrated weight is lowered onto a shaft resting between two support points and resistance to the weight is measured by a strain gauge. Repeating the measurement at short intervals (e.g. 1") indicates local stiffness at multiple points through the length of the shaft.

Basic EI analysis shows that stiffness distribution can vary substantially among shafts having the same flex ratings as determined by oscillation-frequency clamp methods. EI graphs reveal subtle as well as major regions of stiffness variation engineered into the shafts by design and manufacturing. These variations are not revealed or even hinted at by simple letter or number rating systems.

The EI graph of stiffness distribution versus length shown here and on our website home page illustrates four "R-flex" shafts with dramatically different EI profiles that were selected on the basis of having identical R-flex frequency measurements. Golfers will feel different degrees of stiffness and control depending on how they load swing energy through the downswing and impact zone.

Bottom line is that stiffness is a complex property of a golf shaft that cannot be adequately described by single letter or simple number systems in their various forms. Fitting and buying clubs with a reliance on retail flex ratings has little value if maximizing shaft performance for an individual golfer's swing mechanics is a goal. The great value in professional club fitting shows personal testing to identify the right combination of shaft and clubhead for each golfer is by far the best strategy in optimizing clubs.

John Taylor

John Taylor

Reader Comments