Shaft EI stiffness profiles have come of age in characterizing the flex of a golf shaft. EI profiles have replaced shaft butt flex -- the typical L,A,R,S,X designation of flex in its various forms -- as the key measurement of how a shaft bends during the swing. What is EI and how does it help you get fit for the right golf shaft to match your swing?

EI is an engineering term that describes the effects of shaft material elasticity (E) and geometry (I) on resistance to bending -- e.g., stiffness. The distribution of stiffness along the length of a golf shaft depends on the materials used and its construction techniques in manufacturing. Graphite fiber properties and resins that bind graphite fibers (E), as well as wall thickness and local shaft diameter (I) are among the many factors that contribute to EI.

Why does EI matter? A golfer who begins the downswing with a powerful pulling movement will put different bending forces on the shaft than a golfer who begins the downswing with a smooth gradual movement. Similarly, at impact an early wrist release, a late release, a hold and flip release, and wrist rotation - flexion - supination changes exert distinct bending forces on the shaft. Matching EI stiffness properties to these swing mechanics bending forces has major effects on distance and accuracy. It's the heart of modern clubfitting.

The most detailed and useful EI data comes from a 3-point measurement system. The shaft is held by thin supports located 10 inches apart, a calibrated weight is lowered onto the mid point of the shaft between the supports, and strain resistance is quantified. Measurements at one-inch intervals yield an EI graph that shows how stiffness is distributed along the length of a typical shaft. Deriving EI graphs by alternate methods lacks the resolution of 3-point systems.

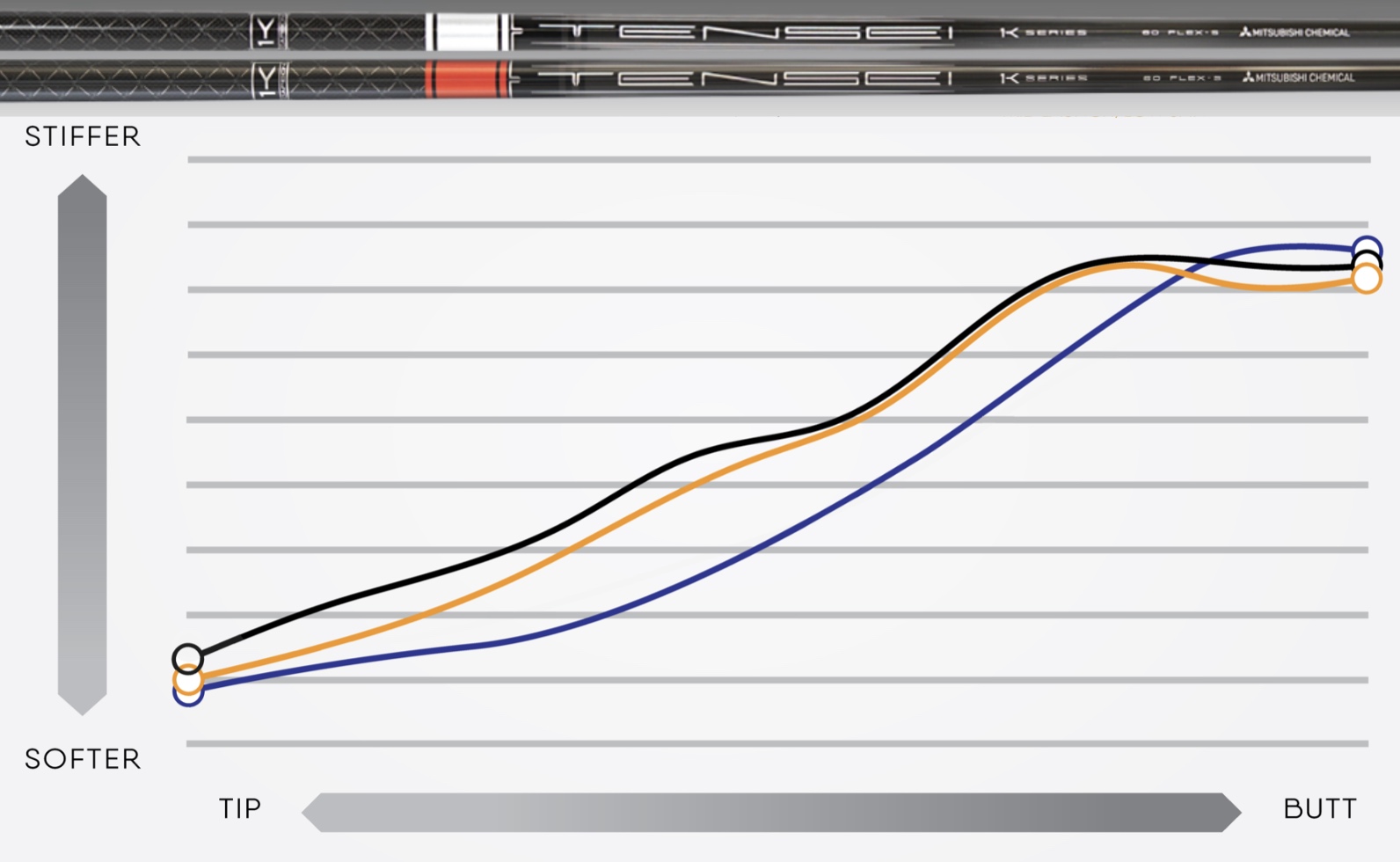

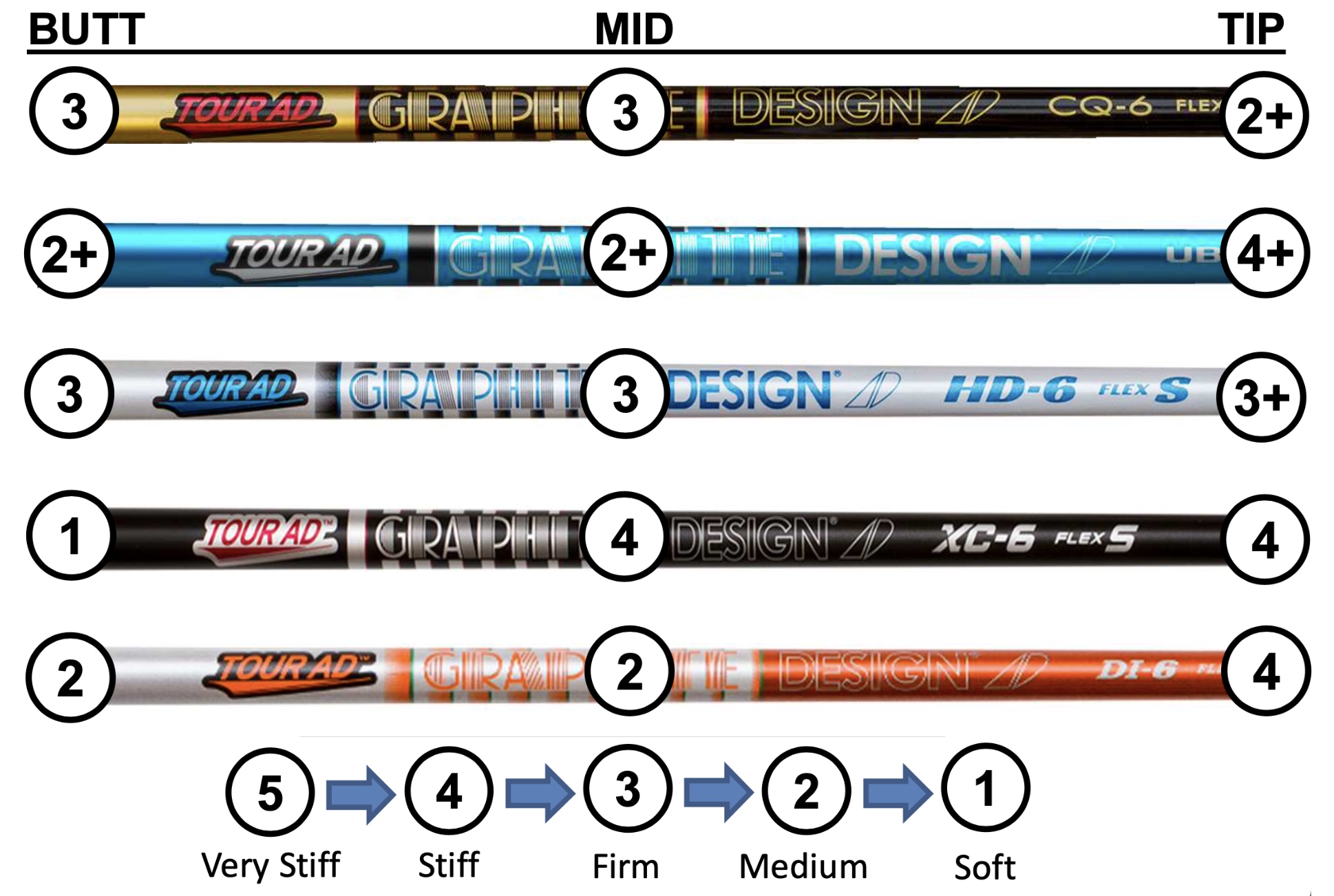

To see how EI helps us, here are EI profiles of four driver shafts from the same manufacturer designed for different performance properties. We compare the data to deflection graphs in which the bending resistance of the shaft is measured at 2-inch intervals from the tip in response to a standard deflection force applied to the tip.

Deflection is widely considered a direct indicator of how the shaft might respond to bending forces during the swing -- think of the inertial resistance of a clubhead in the downswing as equivalent to the tip deflection force in our measurement system. The two graphs show that stiffness engineered into the tip region affects bending in mid to butt region.

These four shafts have the same butt flex and same total weight. The EI plot from butt to mid section is quite similar in all four shafts. In contrast, the Tip to Mid sections show substantial EI differences. The red-line shaft has an increase in stiffness peaking 16 inches from the tip, the green line shaft has a stiffness peak 14 inches from the tip and at lower magnitude. Both blue-line and orange-line shafts have linear changes in EI with the orange-line shaft having a softer tip than the other three shafts.

In measuring deflection, the shaft butt is immobilized and the amount of force required to displace the tip by a constant amount is measured. Greater force is required to deflect the red-line shaft than the other shafts, and resistance to deflection is distributed throughout the shaft approximately proportional to EI differences limited to the tip region.

These graphs show that increased EI stiffness in tip-mid regions of the red-line shaft and green-line shaft transmits greater bending resistance to the mid-butt regions where EI differences are minimal. The position and magnitude of the tip EI peak affects the extent of deflection in the mid-butt region. These effects are consistent with why shafts that measure the same butt flex by widely used low-resolution L,A,R,S,X methods can have large differences in performance and feel for different golfers.

To get full clubfitting benefit from knowing the details of shaft stiffness distribution, we need to determine how and where a golfer transmits maximum rotational energy to the club in the downswing. The goal is to select a shaft that allows for maximum clubhead speed to be delivered to the ball at impact. Clubhead speed translates directly to distance. Shaft stiffness distribution, together with shaft torque properties, also influence clubface orientation at impact, a key factor for accuracy.

Data from the 3-point EI measurement system yields insight into stiffness distribution along the length of the shaft. Swing analysis using a combination of 3D motion capture (e.g., the K-Vest) and high speed video reveals the kinematic sequence and key mechanics of how a golfer swings the club. Taken together, these technologies help a golfer find the right shafts for their clubs.

jtclubs San Francisco, Dec 2014

John Taylor

John Taylor