How Shafts are Made

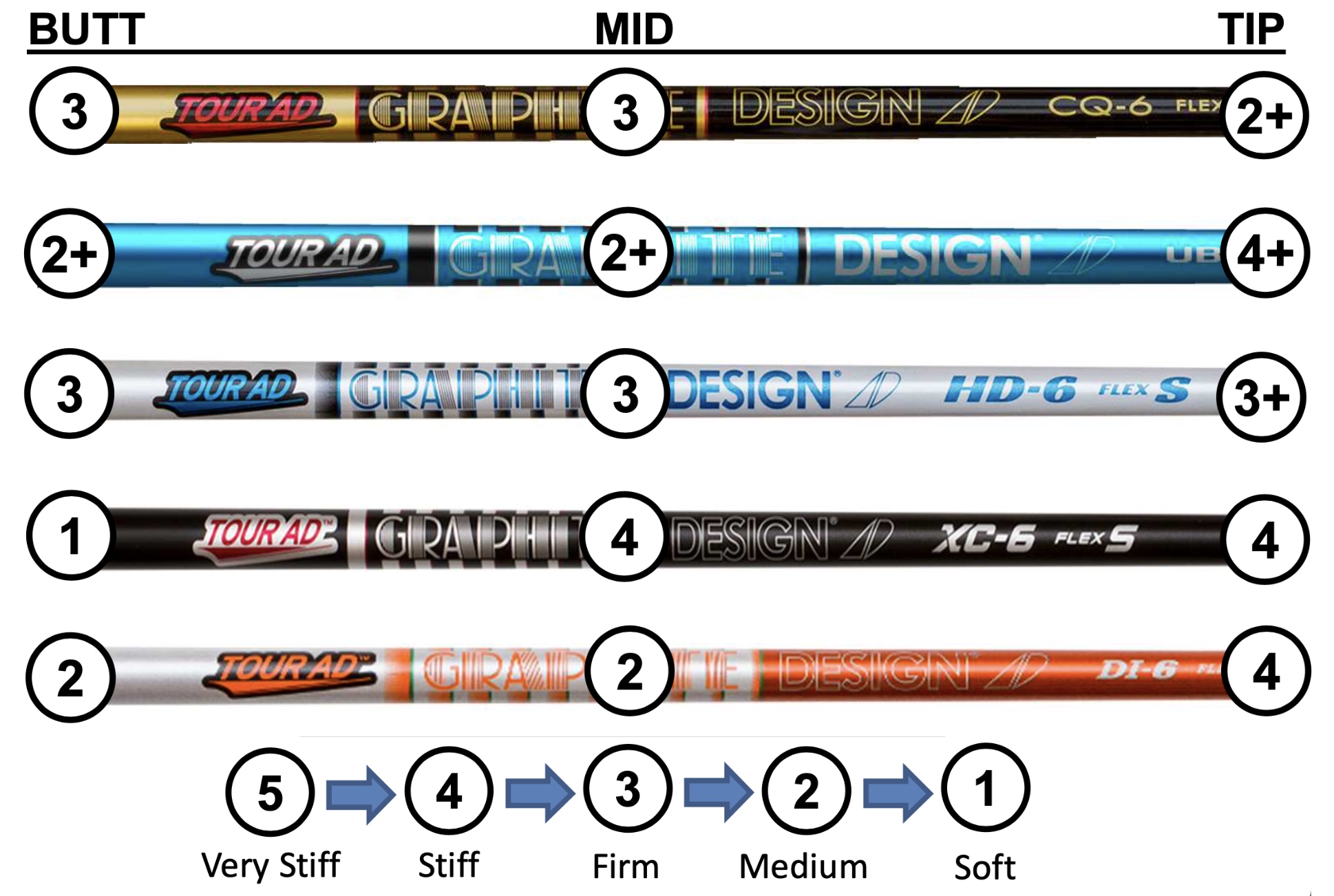

GRAPHITE SHAFTS are constructed from 10 - 20 layers (sheets) or more of carbon fibers impregnated with specialized resins and supplementary compounds. These “pre-preg” sheets can be cut into strips and patterns then overlayed according to a unique pattern on a tapered rod (mandrel) that gives the shaft its final shape. Graphite fiber sheets of different grades can be intermixed with layers of different materials and thickness to strengthen or soften in predictable ways. Exotic (translation: expensive) materials like zylon and boron are examples of fibers that soften or firm the feel of a shaft.

The composition of resins used to hold the graphite sheets together can be varied and specialized fillers (e.g., nanotubes) can be added to help achieve a specific feel. After the graphite sheets are impregnated with resins and wrapped around the mandrel, they are baked in an oven then smoothed by a sanding process to yield shaft tubes ready for a lacquer finish, graphics, and testing.

The shaft engineer has unlimited design options to meet a distinct performance goal. It’s why shafts can have widely different bending properties that should be fit to the mechanics of your swing. We think of most OEM factory stock shafts as place-holders for the club head and grip that are waiting for custom work by your clubfitter. Unless, of course, you have your custom clubs built from the ground up. And in case you wondered, steel shafts have more than a few design options too, but that's a topic for another post.

John Taylor

John Taylor

Reader Comments