Shaft Deflection and EI

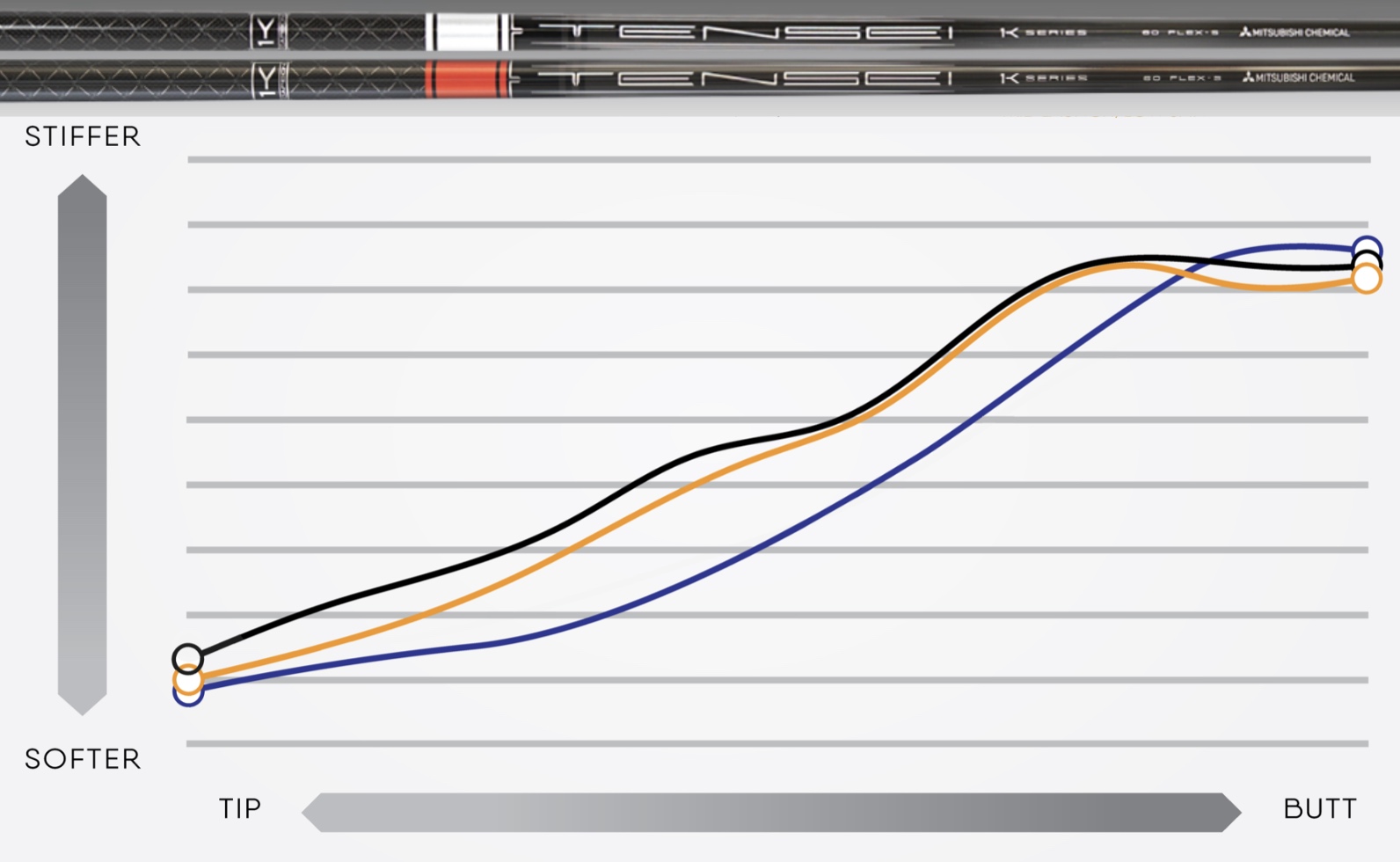

RED TIE, BLACK TIE, WHITE TIE, AND RADIX shafts by MATRIX SHAFTS illustrate how variations in stiffness distribution through the length of a shaft affect the way it deflects during the swing. This relationship is fundamental to the way we understand shaft loading and performance.

Shaft stiffness is best understood as a function of EI, where E is a function of the shaft material’s elastic strain properties and I is a function of shaft wall thickness and shaft diameter. We measure shaft EI by a three-point measuring method using our own equipment and software built and developed by Russ Ryden at Fit2Score in Southlake TX.

In this method, a shaft is placed on two support points and displacement pressure by a constant weight lowered between the two supports is measured (with a strain gauge) along the shaft length in one-inch increments. Here are EI profiles of four different shafts having the same butt cpm frequency values (flex) and total weight that we have measured to show how dramatically different stiffness distributions can be engineered into a shaft.

The Red Tie (red line), Black Tie (green line), White Tie (blue line), and Radix Shafts (orange line) have the same stiffness distribution from the butt section through the mid section in each shaft. However, quite different stiffness variations have been designed into the shafts from the mid section to the last measurement point at 6-inches from the tip.

All four shafts have essentially the same stiffness in the 23-26" mid region, but the Red Tie measures much stiffer EI values than the other three shafts just 10 inches further towards the tip. Is this a bend point or a stiffness hinge? We don't think that's a correct representation of this stiffness variation engineered into the Red Tie, or in the Black Tie shafts. Our view comes from examining how the shaft is likely to bend (deflect) during the downswing.

Quantitative measurement of deflection at different points along the shaft length by applying a constant load on the tip section reveals a stiffness load on the shaft that's determined by the EI variation designed into the tip section.

The magnitude of the EI variation affects the rate of stiffness change in the Mid - Butt sections. Distal stiffness is effectively reflected back towards the butt section and is measured as a change in shaft deflection. The rate of stiffness change is smooth and controlled in part by choice of materials and construction techniques. A hinge or bend point effect would cause instability of the club during the swing. EI variations must be reflected smoothly through the shaft to have a positive effect on performance.

In our experience, other methods of examining flex distribution lack the resolution of EI profiling due to the inherent technical limitations of the measurement methods that fial to detect local EI variations. And concepts like "kick point" or "bend point" do not accurately represent the effects of regional EI variations. The importance of measuring EI for understanding shaft performance has been well-documented by Dave Tutelman and others.

The relationship between EI stiffness distribution and downswing deflection is the foundation on which our understanding of shaft performance is built. Torque, total weight, weight balance (swingweight), materials, and manufacturing methods all play a role in performance and feel, but shaft engineering probably starts most effectively with how EI variation is designed into the mid section of the shaft.

A word of caution is warranted when interpreting shaft analytical data. While the deflection curve is giving us an idea about how regional EI inflections are transmitted as stiffness or felt along the shaft, the relationship to shaft performance during the swing will likely be directly related to wrist release through the impact zone. A late release is expected to allow for a greater benefit from shaft technology than an early release.

John Taylor

John Taylor

Reader Comments